Features

How-to

Systems

Fresh Tips: Keys to carbon dioxide removal

April 5, 2021 By From the experts at the Freshwater Institute

Plastic packing media threaded onto nylon rope in a CO2 stripping column at the Freshwater Institute.Photo: Freshwater Institute

Plastic packing media threaded onto nylon rope in a CO2 stripping column at the Freshwater Institute.Photo: Freshwater Institute High stocking densities and efficient oxygenation make carbon dioxide (CO2) concentrations a common limiting factor for RAS designs for some fish species. A CO2 stripper, consisting of a blower to force air upward through a chamber of cascading water, is a typical technique for CO2 removal. CO2 stripping is ideally located after biofiltration, where CO2 concentrations are highest, and before oxygenation to take advantage of aeration that occurs inside the CO2 stripper. In a CO2 stripper, carbon dioxide removal is impacted by water breakup, forced air flow, and the gradient of CO2 concentration in the water.

Packing media

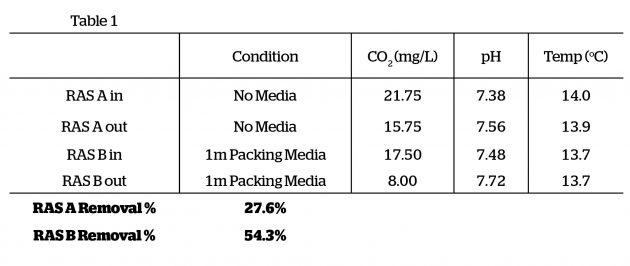

Packing media in a CO2 stripping column breaks up the cascading water and increases gas-liquid interfacial area to increase CO2 removal efficiency. Appropriate packing material includes structured media or random packing media. In a case study recently completed at the Freshwater Institute, single pass CO2 removal efficiency was measured for the CO2 stripper of a RAS operated with or without one metre of two-inch random packing media. The CO2 stripper with packing media removed approximately twice as much CO2 as a stripper operated without packing media. (Table 1)

In this case, the decision was made to include packing media. However, packing media can biofoul over time and create an environment for concentration and growth of organic material, pathogens, and off-flavour-producing bacteria. Because packing media cannot be properly cleaned or disinfected without removing it from the column, it is not recommended for systems dedicated to purging off-flavour and may not be necessary for RAS with low stocking densities. Consider ways to remove packing media for future cleaning and replacement, or for access to underlying areas that may need cleaning and maintenance.

At the Freshwater Institute, packing media is threaded onto water-proof nylon rope prior to installation. The rope allows removal of the media from the top of the CO2 stripping column without the need for scooping or entering the column to reach the bottom. The rope also prevents loose media from falling into tanks or sumps causing downstream plugging and operational issues.

Facility CO2 concentrations

Blown air with lower ambient CO2 concentrations will remove more CO2 than air with higher ambient CO2 concentrations. Facilities constructed to be more air-tight with processes that do not vent high CO2 air can result in high ambient CO2 concentrations in the airspace. As such, it is important to periodically monitor ambient CO2 concentrations in the building and any changes that can result from amended staffing schedules, updated production goals, or seasonal adjustments to heating and cooling systems. The US workplace safety agency, OSHA, reports that the permissible exposure limit of CO2 in an eight-hour workday of a 40-hour week is 5,000 ppm. However, staff comfort and CO2 stripping performance can be negatively impacted at ambient CO2 concentrations as low as 1,000 ppm. Elevated CO2 in the ambient air could be a factor if dissolved CO2 is accumulating unexpectedly in a RAS.

Regular checks and maintenance

RAS managers should closely monitor dissolved CO2 concentrations and regularly inspect CO2 stripping process equipment for normal operation. Be sure that water flow rates and air volumes are correct and service or replace underperforming pumps or blowers. Confirm that outside air vents are securely connected and unrestricted. Periodically check media for fouling and pooling water in the stripper column and plan to remove and clean or replace media accordingly. Good preventative maintenance will ensure continued CO2 stripper performance.

For more information please visit www.freshwaterinstitute.org.

Print this page