Virtual Event

RAS Virtual Summit 2022

October 6, 2022 at

11:00am ET

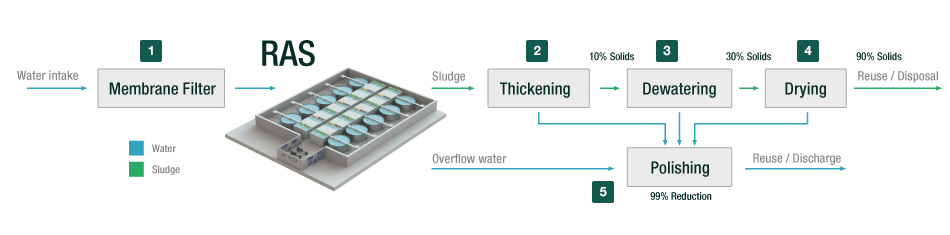

Customized turnkey solutions for aquaculture effluent treatment

Alumichem supplies customized turnkey solutions to treat intake water and effluents from RAS/fish farms. The effluents are typically from backwash of drum filters and biofilters as well as overflow water. The solutions are designed specifically for your need, local conditions, and any environmental regulation. We help you to maximize performance by supporting you before, during and after start-up.

Our solutions have the following advantages:

- Removal of solids, nitrogen, phosphorous and heavy metals

- Lower cost of sludge handling and conversion into a valuable resource

- Modular and automated design allows easy integration into new and existing fish farms

- Reuse of treated wastewater

- Limited footprint

- Perfect chemistry and technology interaction

Meeting your stringent discharge requirements

The requirements for wastewater treatment and discharge are becoming stricter – both in Europe and globally. By partnering with Alumichem, you are guaranteed the system solutions comply with your current environmental legislations and you will receive peace of mind that they can be adapted for any future requirements.

Solutions for RAS intake and effluent treatment

- Water intake filtration

Alumichem supplies solutions for membrane ultrafiltration of your intake water to ensure safe fish farm operation. This will be designed according to your needs ensuring protection against harmful substances like bacteria, vira, heavy metals etc.

- Sludge thickening

The initial sludge thickening step takes the dry matter content from 0-1% and up to 10% solids and significantly reduces the sludge amount

The process consists of two parts:

– Chemical conditioning of the sludge to build large flocs

– Mechanical filtration to separate these floc particles from water

After thickening, the sludge is ideal for biogas production

- Sludge dewatering

The thickened sludge can be further dewatered in a dewatering step, in which the dry matter content can reach 30% solids and the sludge amount is further reduced for easy transportation.

After the sludge dewatering step, the sludge is ideal as fertilizer in local agriculture or as carbon source in a composting facility.

- Sludge drying

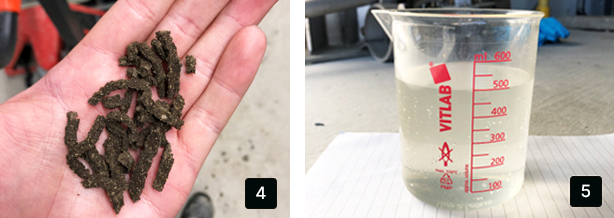

The dewatered sludge can be further treated in a sludge dryer. In this step the dry matter content can reach >90% solids and the dried sludge is hygienized for easy and safe handling and storage, e.g., in bigbags

Alumichem uses very energy efficient heat pump dryers. The dried sludge contains high value nutrients and energy, which can be utilized in production of fertilizer or thermal energy.

- Polishing of discharge water

The reject water from the sludge treatment steps and any overflow water from the RAS plant is polished before discharge/reuse to ensure compliance with any environmental regulation

The water can be treated for any remaining solids, nitrogen, phosphorous, TOC, heavy metals etc.

4 dried sludge discharge. 5 clean water discharge

A selection of our effluent treatment partners:

Learn more at: alumichem.com/applications/aquaculture-sludge-treatment/

Aquaculture Effluent Treatment

Our solutions have the following advantages:

- Removal of solids, nitrogen, phosphorous and heavy metals

- Lower cost of sludge handling and conversion into a valuable resource

- Modular and automated design allows easy integration into new and existing fish farms

- Reuse of treated wastewater

- Limited footprint

- Perfect chemistry and technology interaction

Learn more at: www.alumichem.com