News

Industry update

Freshwater

Management

Technology

New York RAS farm ramps up post-harvest processing with new freezing tech

October 27, 2020 By RAStech staff

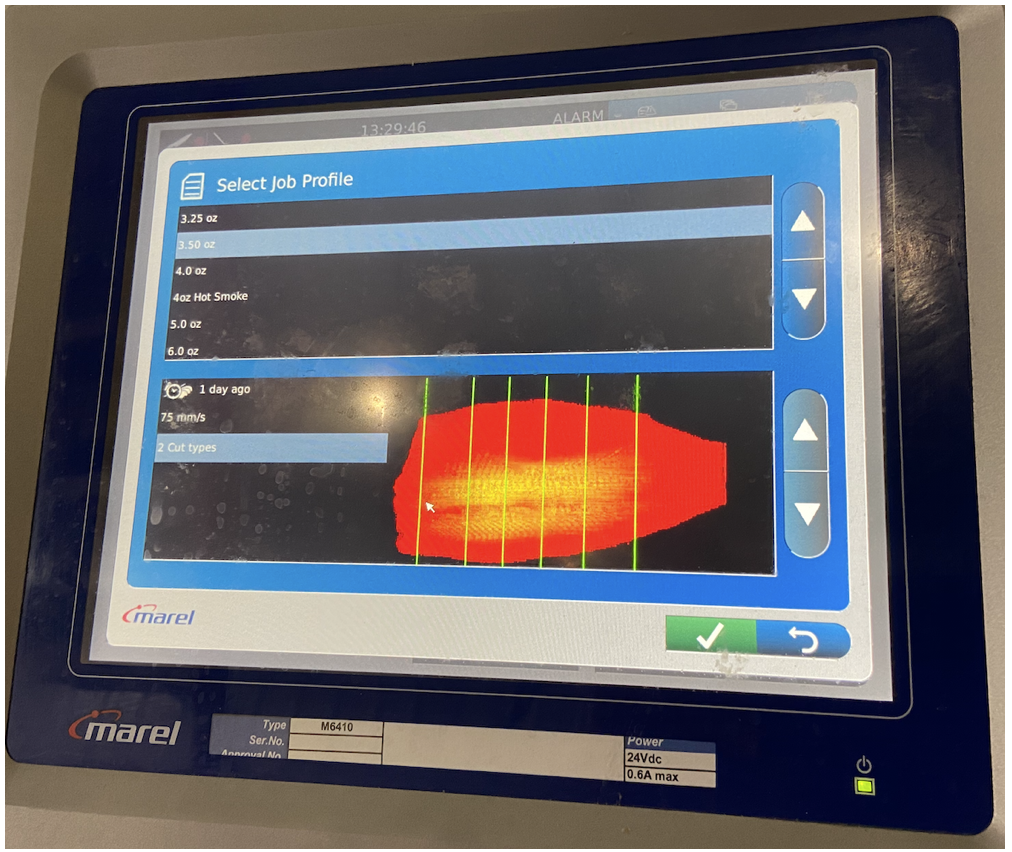

Marel portioning machine measuring 3.25oz portions

(Photo: Hudson Valley Fisheries)

Marel portioning machine measuring 3.25oz portions

(Photo: Hudson Valley Fisheries) Hudson Valley Fisheries, which farms steelhead trout (Oncorhynchus mykiss) in RAS, has installed state-of-the-art Marel portioning and grading/sorting machinery along with a nitrogen freezer tunnel.

With this installations, the Hudson, New York-based aquaculture firm becomes the first steelhead RAS farm in the U.S. with on-site turnkey portioning and freezer tunnel capabilities. The company handles primary and secondary processing in-house at its HACCP-compliant 163,000 square foot RAS facility.

Hudson Valley Fisheries will portion and flash freeze on demand to fulfill custom orders, as it does with its fresh orders. Portions of any size, both skin on and off, are available in both fresh and frozen formats, the latter having a six-month best date from date frozen, the company said in a statement.

The new equipment will enable Hudson Valley Fisheries to take advantage of Individually Quick Frozen (IQF) technology, which offers multiple benefits including preservation of product nutrients, flavor, aroma and textural integrity. Because the process of rapid freezing prevents the formation of large ice crystals which can damage tissue fibers in the cell walls, thawed IQF products are 95 per cent indistinguishable from fresh. IQF also offers the benefit of individual pieces staying separate when stored. This is important for food sustainability, as the consumer can defrost and use the exactly needed quantity without having to break pieces apart, the company explained.

“Providing our discerning customers with accurate, efficient and easily customizable portioning and the highest-quality IQF technology is a critical step in expanding our capabilities, brand and footprint,” said Hudson Valley Fisheries general manager Ed Tribe. “As a producer focused on sustainability, environmental stewardship and production streamlining, we can now offer customers exact custom portioning, consistency and uniformity, components that are essential for food service, restaurant and retail supply chain management. This technology dovetails with our hands-on approach in ensuring the highest quality product from hatching to grow out and processing. We call this ‘tank to freezer’ and never lose custody of our fish so customers are assured they get exactly what they want and order.”

The Marel portioning and grading/sorting technology will facilitate applications such as grading, portioning, trimming, IQF freezing, batching and packing. Marel Innova’s production management software generates detailed and valuable information on throughput, yield and quality. Hudson Valley Fisheres is using the IQF tunnel to create the “industry’s highest integrity flash-frozen product in seconds, offering customers an extended life cycle and complete flexibility” to build up an inventory of its products.

“With the pandemic constricting imported seafood supply chains, our fully traceable, U.S.A.-raised and processed steelhead is an attractive option for consumers and retailers alike,” Tribe said. “While there has always been consistent demand for our head-on gutted whole fish, which we deliver within hours of humane harvesting, orders for our fresh fillets have increased substantially along with individually portioned, vac-packed IQF fillets. People want seafood they know is safe, pure, sustainability grown, easy to prepare and healthful. We check all those boxes.”

Reducing off-cut trimmings is a primary concern at Hudson Valley Fisheries, which is humanely harvesting 15,000 pounds of antibiotic-, hormone- and vaccine-free steelhead each week. The Marel technology provides multiple checkpoints throughout the processing journey for the Hudson Valley Fisheries processing team to ensure each fillet is the ideal size, weight and quality while preserving as much flesh as possible. In the coming months, Hudson Valley Fisheries will use portioning trimmings in patty development. In addition to whole fish and fillets, the company recently debuted a cold-smoked product and will soon offer a hot-smoked line of steelhead.

Seamore’s, a sustainable seafood restaurant with five locations in Manhattan and Brooklyn, and recipient of the Menumaster Trendsetter for sustainable, approachable seafood, has replaced its salmon dishes with New York Steelhead, Hudson Valley Fisheries’ flagship brand. Steelhead is an ideal alternative to salmon with its beautiful orange flesh, velvety, lean texture and clean, mild flavor.

“Locality and sustainability will grow in importance as food supply chains weaken and break. U.S. seafood production, lagging behind its global peers, needs to catch up and look to land-based models like RAS to meet consumer demand while safeguarding the environment,” Hudson Valley Fisheries president John Ng explained. “In the U.S., 80 per cent of the fishing industry’s catch is exported and 90 per cent of seafood Americans consume comes from imported sources, entailing enormous monetary and environmental cost with trans-Atlantic transport. We want Americans to eat domestic seafood and inspire more land-based RAS farming models that sustainably raise multiple seafood species. We want to contribute to a healthier ecosystem for humans, fish, wildlife and the environment.”

Print this page