Opinion

Management

Research

Technology

Engineer’s view: ‘RASed’ about MCR

’m all RASed up about this new technology called a mixed-cell raceway (MCR).

April 22, 2019 By Michael Ben Timmons

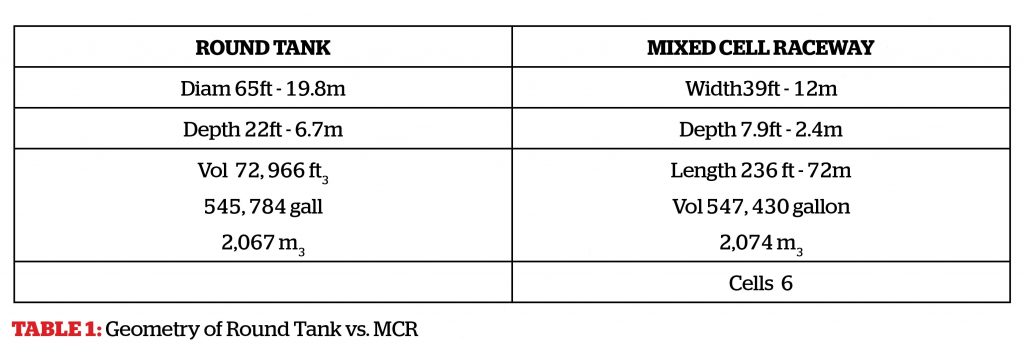

Table 1 In my current class teaching senior engineering students

Table 1 In my current class teaching senior engineering studentsI told my students they are about to become RASed about recirculating land-based aquaculture. I’m not sure they completely grasped this new term, but as the weeks go by in the semester the students are really starting to embrace the term.

Well, I’m all RASed up about this new technology called a mixed-cell raceway (MCR). I wrote about MCRs in the last issue of Hatchery International. In that same issue (Vol 20 Issue 2 March/April 2019) immediately following my article was the piece, “Miami turns blue,” an update on Atlantic Sapphire’s project to construct a massive land-based salmon farm in the U.S. There were some great pictures of the project that showed the massive scale of an individual rearing tank (22x65ft or 6.7m x 19.8m with 546,000 gallons or 2,067 cubic meters). This type of tank scale volume is necessary to make the required capital investment efficient and provide competitive economic returns to conventional net pen salmon production systems. No argument here, but is this the type of system you or the fish people on your team want to work in on a daily basis? One thing for sure is that you’d need to have plenty of safety flotation devices (life preservers) hanging all over the place in case someone accidentally tripped or slipped and fell into the 7-meter-deep fish tank.

When we were developing the MCR concept a few years back, I asked my good friend John L. Holder, who has more than 30 years of experience working with salmonids in both raceways and net pens, what would be his ideal depth in a raceway to manage the salmon effectively. And his answer was 1.5 to 2 meters. Well, 2 meters is a lot different than a round tank that is 7 meters deep.

I was in a recent conversation with a project team leader that is building a large indoor land-based farm and we were arguing, I mean discussing, some subtle aspects of design and tank layout. The issue revolved around being able to fit a number of MCR tanks into an existing building space and how much space was needed between adjacent MCRs for people activity, i.e., fish management activities. Basically, the discussion ended up with the age old saying of me telling the other fella, “You don’t know what you don’t know.”

New teams entering this arena of indoor aquaculture (where space is a premium) always underestimate the critical aspect of being able to effectively and conveniently conduct the day-to-day chores of managing a fish farm. If the design layout makes it difficult for the fish folks to do their job, then one or two (or maybe both) things will happen: 1) the job or task will be done poorly or at greater effort, or 2) not done at all or as often as it should be.

Using John Holder’s ‘wish’ that a tank should only be about 2 meters deep, I did a calculation (see Table 1) on the size of a MCR compared to the Atlantic Sapphire round tanks. After looking at this table and studying it some, do you see why I’m all RASed about the MCR? We can create the same tank volume using a conventional raceway footprint (with MCR adaptation) and still have reasonable and very manageable water depths. The only thing I really think works negatively against the MCR is that if you are going to use the shallow depth (2 m) then your floor foot print is going to be roughly double the footprint of a round tank (that takes up a square foot print, i.e., round tank diameter expressed as a square area). You could increase the depth on the MCR, but then you get back into fish management issues. But why do you need a building in the first place? Why not use tank domes? That’s another discussion for another column.

Anyway, I am RASed and after reading this, maybe you’ll be a little RASed as well. Here is the recently published paper on the MCR tank hydraulics using CFD analytics of various configurations and operating conditions to maximize the effectiveness of the MCR design.

For those who want to study RAS principles a bit more or review the basic principles, let me encourage you to take advantage of a newly created distance course, or look into the Aquacultural Engineering Society’s offering of a certification in RAS design.

Michael Ben Timmons is a professor in the Department of Biological and Environmental Engineering at Cornell University in Ithaca, N.Y. He teaches information related to the production of aquacultured products with emphasis on sustainable and environmentally friendly engineering technologies.

Print this page