Features

How-to

disease management

Management

Biosecurity 101: Keys to keeping your RAS pathogen-free

November 11, 2020 By Saravanan Subramanian, Bernardo Sumares and Tahi Fu

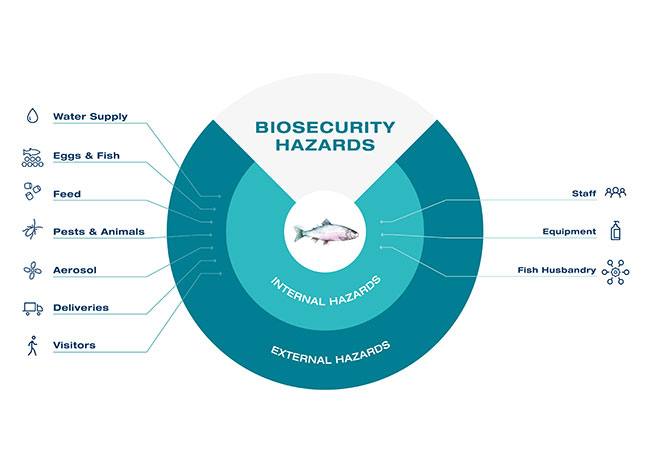

Biosecurity in RAS involves addressing internal and external risk hazards. Photo credit: skretting

Biosecurity in RAS involves addressing internal and external risk hazards. Photo credit: skretting In salmon farming, there is an increasing trend to utilize recirculating aquaculture systems (RAS). While some producers have integrated these systems into their broader operations to establish larger, more robust smolt for grow-out in sea cages, others are using them for the entire production cycle – from egg to harvest.

As these ventures have found, there are many advantages to RAS systems. At the forefront is their capability to provide tighter environment controls. By having stable production conditions, RAS provides the scope to promote consistent growth rates.

Operating any RAS facility is a demanding task, requiring specialist skills and experience. These systems face their own unique set of challenges, including a range of risks associated with water quality and biosecurity. To minimise fish stress and related susceptibility to disease, it is essential that stable conditions are maintained within the system and that robust biosecurity measures are implemented and followed.

One of the key advantages of RAS facilities is the physical barriers and control measures that they offer to protect fish from external, disease-causing pathogens. Nevertheless, pathogenic microbes can prevail in different forms in and around RAS farms, and given the right conditions, they can rapidly increase in number and spread. This in turn can lead to a disease outbreak situation, and eventually fish mortality – causing financial loss to farmers.

The most common pathogens found in RAS are protozoan parasites (e.g. Amoebas, Costia), fungi (e.g. Saprolegnia, Aphanomyces), bacteria (e.g. Vibrio, Aeromonas) and viruses (e.g. ISA, IPN).

Despite the physical separation from external hazards, RAS can still be very fragile if biosecurity measures are not implemented and strictly followed.

Hazards are divided in two main categories: external and internal. External hazards are transferred from the exterior into the RAS facility. Internal hazards are those that arise and spread within RAS facilities. Each hazard has a different means of entry, a distinctive rate of spread, and will carry its own level of risk.

Water supply

Water is an essential element in any fish farm and the quality and safety of intake water varies depending on the source. Water can be supplied to the RAS facility from ground water like borewells or surface waters like rivers, lakes and fjords. Regardless of the source selected, water entering the production tanks must be free of particles (e.g. sand), pathogens and contaminants (e.g. copper, zinc and aluminium).

Groundwater sources are relatively safe, as they are pathogen-free, low in microbial and organic load compared to surface water sources. Therefore, more attention and measures are required for surface water supply. For contaminants, the risk is quite similar for ground and surface water supply source. Undesirable contaminant levels in surface water sources can be influenced by natural weathering, as well as industrial and agricultural runoff.

One of the first lines of biosecurity begins at this point. Good mechanical filtration measurements are taken to mitigate particles. This is followed by ozone to mitigate microparticles, pathogens and contaminants. Then, UV measurements are taken to mitigate pathogens and remove any excess of ozone in the water.

To reduce the risk of breakdown and to maintain equipment efficiency, it is important to carefully follow the manufacturer’s instructions with regard to the correct contact time and dose in UV and ozone units. Weekly maintenance and daily check-ups should be in place and key components such as UV lamps should be replaced before reaching the end of their expected life.

In case of unexpected failures, it is advisable to keep backups of key components in stock for replacement and to have standby units for emergency use.

As a biosecurity traceability procedure, monthly water samples should be taken before and after treatment to check effective functionality. Monitor contaminant levels in the supply water on a yearly basis.

Eggs and fish

A regular year-round supply of eggs and fish is a prerequisite in RAS, which involves meticulous logistics planning to obtain high-quality and pathogen-free supplies.

Allowing eggs or fish carrying pathogens into a RAS facility can have a huge operational risk and financial impact. The production plan will be disrupted, the entire infected rearing unit will have to be cleaned and thoroughly disinfected, and the fish will have to be culled. In a worst case scenario, pathogens will spread to other rearing units. Any stop in RAS operations due to a biosecurity breach will lead to a substantial delay and loss of fish production.

Most local authorities request a health certificate from egg and fish suppliers to mitigate spread of infectious diseases. Suppliers have to be quality assured, requiring screening for infectious pathogens. This procedure must be conducted prior to shipment to the buyer.

It is advisable to request a disinfection certificate for the eggs and transporting system. Eggs should again be disinfected upon arrival and fish should be stocked in quarantine units. The quarantine period varies and depends of several factors, but as a general rule, four weeks is advisable.

Before stocking animals, experienced technicians or veterinarians should conduct an assessment to evaluate stock quality and any underlying health issues post-transport. A good welfare recording system should be in place. Traceability is an important tool in case a disease outbreak arises.

Visitors

Visitors can be common to RAS facilities and will be present for a variety of reasons. However, such visitors can unintentionally carry and spread pathogens that are infectious to fish and also to facility staff.

Different approaches can minimize these risks. For instance, any new arrival to the facility needs to be informed about its biosecurity rules. They should also complete a visitor form, confirming that they have not been exposed to any potential risks or been on sick leave in the past 14 days. Most facilities further suggest a 48-hour quarantine period after visiting other fish farms or places posing a biosecurity risk.

Physical barriers separating visitors from production areas are also effective. However, they are expensive and need to be planned in the initial building phase. Simple physical barriers can be implemented with lower costs, such as separating unit entrances and creating changing areas. These areas should be equipped with footbaths, hand disinfection stations and a changing room.

Before entering the RAS, visitors should change into fresh overalls and footwear. They must also clean and disinfect their hands, and avoid any direct contact with the production process. In the case of sampling, staff should provide support to avoid unnecessary risks.

Feed

Feed-related risks can be linked to microbial and physical quality. Nutrient-rich feeds offer the means for pathogens to develop and spread, depending on the storage conditions. However, the microbial risk of feed origin is minimal. The risks linked to the physical quality of feeds is important and have indirect effects due to nutrient leaching, as well as the disintegration and behaviour of feed in water.

Today’s commercial fish feed production technologies, like extrusion, expose feed materials to high temperatures and pressure that neutralize pathogens.

Biosecurity measures are extremely important to reduce indirect risks due to feed physical quality. At delivery, all feeds should be inspected. A sample should be taken, labelled and frozen for future analysis (if required). In the sample, it is important to analyze dust, breakage and oil leakage. Keep a good recording system in place, to ensure traceability if any problems do arise.

Feed should be stored appropriately in a cold and fresh room or silo, and when smaller feed types are opened, they should be properly closed to avoid deterioration or contamination.

Feeding systems should be checked and maintained on a weekly basis. A feed sample should be taken when reaching the end of the feeding line to analyse dust and breakage. Small particles of feed released into the water can lead to serious consequences. Any feed accumulation or mould should be immediately cleaned, especially in feeding systems to avoid spreading to other feeds.

Deliveries

Deliveries are part of RAS facility operations and traffic can occasionally be high. Pathogens can also enter the facility through deliveries and these can rapidly spread if no biosecurity measures are in place. It is recommended to establish a delivery area and a place where relevant goods can be disinfected and placed in quarantine.

Disinfection logs from the carrier should be requested to ensure there are no risks from previous cargo, stating the type of chemical used and completed date.

Always ensure that goods are from certified sources, especially those products that will be directly used in the system. Never use equipment that has been in other facilities, even disinfected, as the risk is too high.

Aerosols

Aerosols are small suspended particles in the air, like dust, that can gradually accumulate and settle on surfaces. Airborne particles can also carry pathogens into the facility through the ventilation systems.

Because it is difficult to trace, this external hazard is not commonly mentioned as a problem in RAS operations. It is recommended to have a filtration system to minimise the entry of particles, and when possible, ventilation systems should be installed specifically in each unit.

Wherever possible, ventilation outlets and fans should be placed away from tanks, equipment and sump areas where aerosol and droplets can easily come into contact with the water in the system. Monthly visual inspection of ventilation systems is recommended and filters should be changed frequently.

Pests and animals

RAS facilities are less exposed to pests and animals than traditional fish farms. However, they still offer stable temperatures, food and safety from predators, thereby creating the perfect environment for potential pests like insects, rodents and scavenger birds.

These pests and animals are external hazards that could carry pathogens into the facility. Some could stress the fish which eventually can lead to welfare and health issues. Other related biosecurity risks include damage to feed bags and electrical systems.

A certified pest control company should assess the control of pests and animals. Staff should be pro-active about removing and cleaning any feed spills immediately, and ensuring that the facility is tidy, organised and free of accumulated waste or materials.

Staff

Staff are the most important element in RAS operations. They are responsible for implementing and following biosecurity protocols while also ensuring risks are avoided.

There is a high risk of pathogens spreading through the facility via staff members due to their daily activities and direct contact with fish and systems. Team members should be sufficiently skilled to perform any type of operation in the facility, but it is important that the team has a specific production unit or a specific batch of fish to follow, as this reduces cross-contamination risks.

Staff discipline is essential. Good hygiene and specific working clothes are important measures. Keep footbath stations cleaned and refilled with active disinfectants. Disinfectants can lose their efficiency fast depending on usage, so ensure they are replaced regularly. Solution guide tables can be displayed at the relevant area as a reminder.

Good awareness training and culture is also important. In the event of disease outbreak, maintain different staff shifts to avoid cross-contamination.

Equipment

Good equipment and tools are key for smoother, more efficient operations. They also boost team morale, save time and contribute to biosecurity.

A huge risk of cross-contamination is associated with the use of equipment between operational tasks and units. In particular, this can occur when using equipment from grower production units in hatchery units, in which fish are more susceptible and fragile.

Good biosecurity practices involve the cleaning and disinfection of all types of equipment after use – removing fish mucus, scales and organic material clinging to the equipment. If not thoroughly cleaned, theybecome susceptible to bacterial growth, causing bad odor and a potential source for disease outbreaks.

Disinfectant residues on equipment have to be rinsed before use. In some cases and the material allows, disinfected tools should be left to air-dry until next use. Procedures can differ from manufacturer, type of product and concentration used but as a general rule, a disinfectant should be in contact at least 10-20 minutes before removal. Every surface should be physically cleaned to remove as much organic material as possible before disinfection.

Another good practice is the use of color codes in operations. This simple and effective method can be applied to all types of operations – from the removal of dead fish to feed preparation. This brings a range of benefits: minimising cross-contamination, improving hazard awareness, and providing quicker access to the required equipment.

Fish husbandry

Bio-accumulation and mortalities in the RAS system promote the development of organisms like pathogens, increasing the risk of diseases outbreaks. By keeping a healthy system, the chances of pathogens growing and spreading are highly reduced.

When faeces and uneaten feed are not effectively removed from the RAS system, bio-accumulation is expected. It is important to have good fish husbandry routines implemented to ensure active removal. Biofilm removal from the tank walls and sump areas should be monitored and cleaned. Deposits of uneaten feed and organic matter should be cleaned and syphoned if required.

Other associated risks include the removal of mortalities from the system. This activity should be taken with extra precautions, and it is advisable to use specific equipment, designate specific areas to classify fish mortalities, and use disposable gloves. The disposal of dead fish should follow local regulations and be collected by a certified company.

Designated specific areas, floors, walkways and all type of surfaces should be cleaned and disinfected after each operation.

Biosecurity measures prevent and minimise the spread of pathogens. Any neglect or breach in biosecurity measures can result in a disease outbreak, which can in turn, require extra labour during operations. It could also affect the RAS facility’s reputation and lead to welfare authorities deciding to restrict production expansion plans, with significant monetary implications.

It is important to develop and implement a strict biosecurity plan alongside your team and to involve different areas of expertise to guarantee that the details are not forgotten. Review and test the plan to ensure all measures are in place. Ensure your team has good biosecurity awareness, as they are the key factor to implement and follow the measures. Use infographics within your facility, they are a powerful tool reminding everyone about the importance of biosecurity. Specific biosecurity training should also be provided with annual reviews.

Essentially, biosecurity starts long before entering the RAS facility. It is important to create a culture of biosecurity awareness throughout your facility to ensure that everyone knows the risks and consequences.

Saravanan Subramanian is the global product and technical manager for RAS at Skretting. He is responsible for developing and delivering high performance fish feed and technical service to RAS customers.

Bernardo Sumares is a RAS technical specialist at Skretting. He is responsible for providing technical support to RAS customers and improving their farm performance and productivity.

Tahi Fu is a project manager and technical RAS specialist for Skretting. His responsibilities include developing services beyond feed and supporting RAS customers in Asia.

Print this page