Features

Technology

Ask the Expert: RAS media filtration, an important aspect of any well-functioning farm

December 30, 2024 By Mike de Maine, Dryden Aqua

Media filtration in recirculating aquaculture systems (RAS) has been around for centuries, but is often so poorly understood, missing the required performance mark.

Media filtration can take many forms including slow gravity filtration, rapid gravity filtration, pressure filtration and multimedia pressure filtration.

The main concepts are simple: dirt is trapped between the media grains during the filtration phase and particles adhere to the grains. In both cases the particles should be ejected during the backwash phase.

The diagram below explains the concepts involved:

Media filtration mechanisms

I believe that it is the perceived simplicity that has resulted in the under appreciation of the complexity of a well performing media filtration system.

Filtration velocity

I suppose the interesting question to ask is what is the right filtration velocity? Well, that is very dependant on your water source quality, what you want to remove from that source, the efficiency of removal you want to achieve and what filtration method you are using.

Below are some of the recommendations and often observed filtration velocities

| Filtration Type | Application | Recommended | Often used | ||

| m/h (m3/h/m2) | gpm/ft2 | m/h (m3/h/m2) | gpm/ft2 | ||

| Gravity filters | Water treatment | 5 – 10 | 2 – 4 | 5 – 10 | 2 – 4 |

| Aquariums | 5 – 10 | 2 – 4 | 8 – 12 | 3 – 5 | |

| Pools | 5 – 10 | 2 – 4 | 10 – 15 | 4 – 6 | |

| Pressure filters & Multimedia | Water treatment | 5 – 15 | 2 – 6 | 5 – 30 | 2 – 12 |

| Aquariums | 15 – 25 | 6 – 10 | 15 – 40 | 6 – 16 | |

| Pools | 20 – 30 | 8 – 12 | 30 – 50 | 12 – 20 | |

| Aquaculture | 10 – 25 | 2 – 10 | 15 – 40 | 6 – 16 | |

Recommended vs. frequently used filtration velocities

Let’s take a step back; why is velocity to important?

1. Water source quality: Due to the lack of ionic charges in soft water that prevents the coagulation of particles to a size that can be filtered out, the filtration performance is generally compromised. Ideal alkalinity and hardness values for good filtration performance is 50 to 150 mg/l alkalinity and 80 to 200 mg/l hardness.

2. Particle size: If your velocities are very high and you are trying to remove mostly fines (sub 10 microns), the slower you filter the more chance that you will allow fine particles to settle out between the media. While at the higher velocities the particles flow with the water stream and through the media bed.

3. Particle density: In any applications where the particles, that you are trying to remove, might be very soft, such as soft organics (notice I separated the Aquaculture application in the table above), the higher velocities tend to shear the particles into smaller and smaller pieces while travelling through the media bed, resulting in very little removal. This same effect is often seen in drum filters too, where the particles are squeezed through the mesh by the differential pressure cause by the water height differences between inside and outside the drum. Our studies have shown that in aquaculture RAS systems the filtration velocities should not be higher than 15m/h or 6 gpm/ft2.

4. Loading rate: In applications where there is a high TSS loading rate (>30mg/l), higher velocities cause a shift from depth filtration to surface filtration and therefore cause a quick increase in the differential pressure across the bed, resulting in particles being sheared into smaller pieces, but also increasing the backwash requirements substantially.

Media bed depth

As media filtration is not a barrier filtration such as cartridges, bags or membranes, it not only relies on surface blockage, but rather on all the principles described in diagram 1. Therefore, the more media depth you have the better your filtration efficiency.

Of course, this is more important when considering a once through flow, such as seawater intakes, and less impactful on recirculation systems or is it? Unfortunately, although the overall thought is that in recirc system eventually all the particles are removed, it is more common that the particles are sheared into smaller pieces and the bulk of small micron particles increases overtime, never actually being removed and therefore contributing to an increasing load which can often be seen in the increasing COD and BOD values (Chemical and Biological oxygen demands).

A minimum bed depth of 750mm of the filtration media grade will ensure the best possible performance for that particular media.

Backwash velocity

Often the most underestimated impact on the overall system performance is the backwash velocity to ensure sufficient media bed expansion to allow for the removal of the dirt.

Somewhere along the line a figure of 1.5 to 2 times the filtration velocity crept into recommendations and in swimming pools where their filtration velocities are 30 m/h and they are therefore backwashing at 45 m/h or 18 gpm/ft2, it can work to sufficiently expand the media and to lift the dirt out the filter, but when you are filtering at 15m/h or 4 gpm/ft2, then a backwash velocity of 22.5 m/h or even 30 m/h (6 or 12 gpm/ft2) is not even enough to expand the bed to allow for the dirt to move out the media never mind lifting that dirt out the filter.

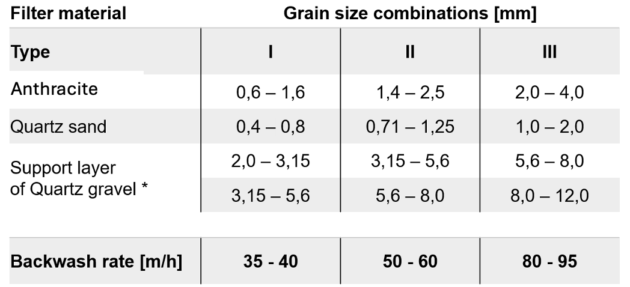

Each grain size has a different expansion vs velocity, but below are some generalizations for good backwash velocities used in industries:

| Filtration Type | Application | Recommended | Often used | ||

| m/h (m3/h/m2) | gpm/ft2 | m/h (m3/h/m2) | gpm/ft2 | ||

| Gravity filters | Water treatment | 15 – 60 | 6 – 25 | 15 – 35 | 8 – 14 |

| Aquariums | 15 – 60 | 6 – 25 | 15 – 35 | 8 – 14 | |

| Pools | 15 – 60 | 6 – 25 | 15 – 35 | 8 – 14 | |

| Pressure filters & Multimedia | Water treatment | 50 – 75 | 20 – 30 | 5 – 30 | 2 – 12 |

| Aquariums | 35 – 45 | 14 – 18 | 15 – 40 | 6 – 16 | |

| Pools | 35 -45 | 14 – 18 | 30 – 50 | 12 – 20 | |

| Aquaculture | 40 – 50 | 16 – 20 | 15 – 40 | 6 – 16 | |

Recommended vs frequently used backwash velocities

However, everything is dependent on the media size and shape you are using i.e. large grain sizes need higher velocities to get them to the require expansion, while elongated media, often found in some glass media, requires very high velocities to get them to expand due to their shape.

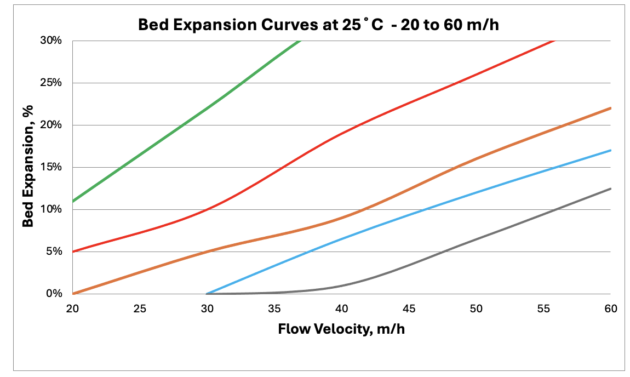

It also depends on the type of particles you need to get rid of i.e. heavy metal particles (oxidized from intake systems) require >5 0m/h or 20 gpm/ft2. Without naming products, the below graph shows just how different bed expansions can be for different materials and even depending on which mine the sand may have come from (red and orange lines are sand media).

The German DIN standard requires a bed expansion of 15 per cent to ensure that the media is separated enough to release the particles from the media, but depending on the specific gravity of the particles, even those that reach the expansion of 15 per cent at lower velocities does not mean that the particles will be lifted out of the filter and that is why most water treatment applications take 40 m/h or 16 gpm/ft2 as a minimum requirement for backwash velocities.

Bed expansion curves of different media at the same temperature and flow velocities.

The below table shows how the velocities can be quite different depending on the grain sizes:

Recommended backwash velocities vs grain size (Evers Water Technology)

Even more importantly and contrary to popular belief, higher backwash velocities actually saves water as shown in the graph below:

The faster your backwash flow the more water you save. Green vs green, Orange vs orange and dark green vs dark green at the different flows 30 vs 60 m/h (12 vs 24 gpm/ft2)

Filter vessel hydraulic design

Over the years and with heavy competition to supply the cheapest filters, the swimming pool industry, aquarium and aquaculture industries have been sucked into using filters that can’t perform to the requirements of the application.

- A promise of filtration velocities of 50 m/h or 20 gpm/ft2, which is shown above is not possible to achieve effective filtration performance.

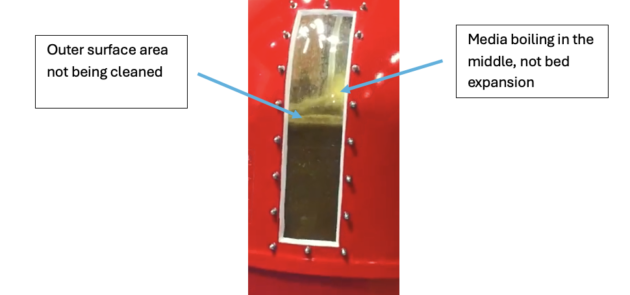

- Poorly designed laterals that are either too short or too large in diameter to properly distribute the flows to create bed expansion instead of boiling the media. This results in only a portion of the filter surface area being used correctly, resulting in preferential flows through a much smaller surface area and therefore operating at much higher filtration velocities than you have designed for.

(Photo: Mike de Maine)

To demonstrate an extreme example that we have encountered before:

The client was filtering at the manufacturers recommendation of 50 m/h and backwashing at 50 m/h, but as the laterals were very short, the filter was only clean a third of the surface area during the backwash, so when recalculating the filtration velocities of the actual surface area being used, the system was filtering at over 110 m/h or 45 gpm/ft2 resulting in no filtration performance, as the particles were just being sheared into smaller and smaller pieces increasing the overall COD and BOD while the water became more and more opaque.

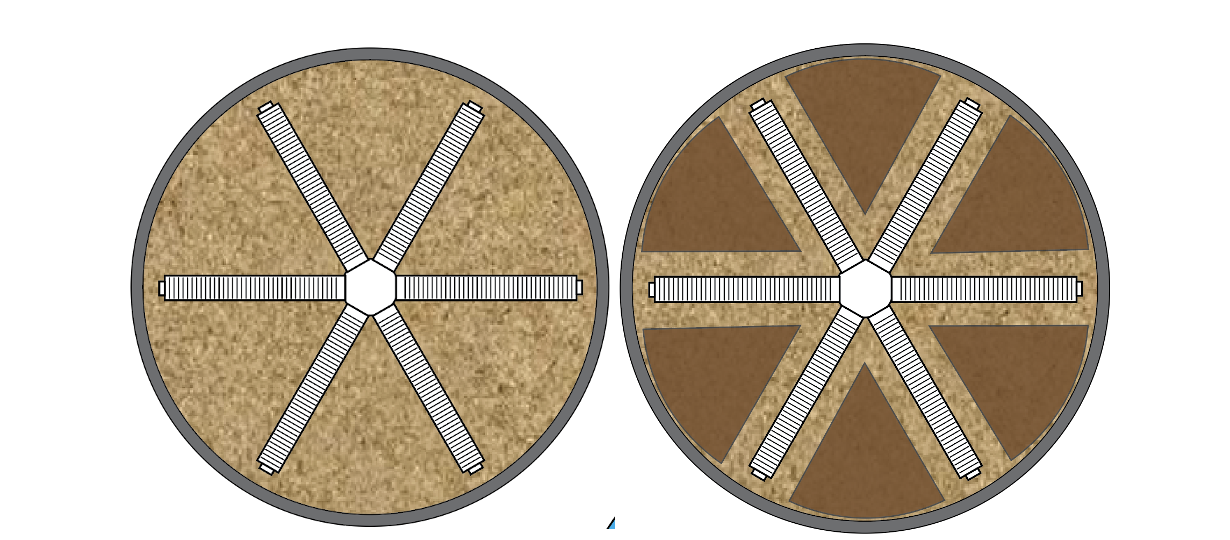

- Filter laterals that do not have a good enough surface area coverage i.e star shaped laterals with too few laterals section and in large diameter filters (>900 mm ). The brown areas in the diagram on the right shows what isn’t being cleaned during the backwash process. In the worst case where the laterals are also oversize in diameter, you would be able to see the star shape on the surface of your media.

Poor star laterals result in most of the beds not being properly used.

- Poorly designed inlet distribution, which causes the media to pile in the middle or around the edges, resulting in preferential flows through a much smaller surface and therefore operating at much higher filtration velocities than you have designed for.

Poor inlet design leads to uneven filtration surface area and preferential flows.

As can be seen above, media filtration can actually be far more complicated than it sounds, but taking a few basic concepts into account, can dramatically improve the performance of your filtration system, the overall efficiency of your system and future design considerations.

Media filtration in aquaculture

Media filtration is often used in intake water filtration, larval rearing flow through filtration, hatchery recirculation, brood stock filtration and wastewater filtration. However, with the importance of fine solids removal becoming more dominant in the overall efficiency of grow out RAS, media filtration is again starting to be considered as a possible side loop solution for cropping out the particles that aren’t being removed by the drum filters and are too big for the protein skimmers.

These particles end up in the biofiltration component and shift the bacterial biome predominantly to the heterotrophs to first break down the particles before any nitrification can happen. This leads to increasing oxygen demands, pH and alkalinity corrections being needed and the requirement for excessive sludge to be removed from the system on a frequent basis.

(Photo: Mike de Maine)

Mike de Maine, is the director of aquariums and aquaculture at Dryden Aqua. He’s passionate about all the technical aspects of aquariums, aquaculture and aquaponics. He had five different aquaponics style systems at his home and also helped with the design of a large scale aquaculture and aquaponics system in South Africa. He wants to help others solve this unassuming problem of filtration.

Print this page